- More than 4000 Installations Worldwide

- +91 9099935527

- mmc@multipackmachinery.com

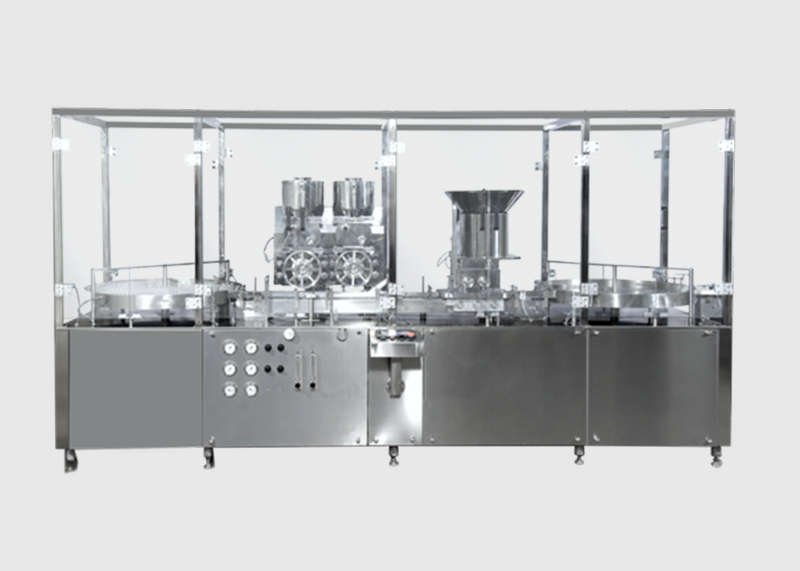

Automatic Injectable Dry Powder Filling With Rubber Stoppering Machine SBPF-240 GMP Model

- Home

- Powder Filling Machines

- Automatic Injectable Dry Powder Filling With Rubber Stoppering Machine SBPF-240 GMP Model

Injectable Vial Dry Powder Filling With Rubber Stoppering Machine

December 11, 2020

Paper Straw Making Machine – Paper straw machine Manufacturer

June 16, 2022Automatic Injectable Dry Powder Filling With Rubber Stoppering Machine SBPF-240 GMP Model Manufacturer, Supplier & Exporter in India

₹2000000.00

Manufacturer Wide range of injectable powder filling machines, vial powder filling machine, dry injection filling machine, vial dry powder filling machine, Injectable dry powder filling machine and sterile dry powder filling machine, Aseptic filling machine manufacturers , aseptic filling machine pharmaceutical , aseptic vial filling equipment , Injectable Liquid Filling Machine, Liquid Filling Machine, Injectable Dry Powder Filling Machine, Dry Powder Filling Machine, Rubber Stoppering Machine, vial filling machine, injectable liquid filling machine, Injectable Liquid Filling Machine, Injectable Vial Filling line , Automatic Injectable Powder Filling with Rubber Stoppering is a compact model used for filling Stoppering of Dry Powder Injectable in to vials with Laminar , HEPA , Glove port, 21 CFR , ISOLATOR , PLC with Touch Screen , RABS and Isolator technology etc…

| Description : |

| Automatic Injectable Powder Filling with Rubber Stoppering is a compact model used for filling Stoppering of Dry Powder Injectable in to vials. |

| Operation : |

| The incoming dry container sterilized are fed through the Unscrambled and suitably guided on the moving delrin flat conveyor belt at the required speed of the correct placement below powder wheel. The sterilized powder is stored in powder hopper is agitated by pair of mechanical agitators for maintaining consistency and uniform bulk density. The powder wheel having eight ports rotates at the pre determined speed below the powder hopper with practically no clearance. Powder wheel consist of Piston in each port and behind the powder wheel vacuum plate is provided there is no clearance between powder wheel and vacuum plate due to back spring pressure. Precise volume of powder is sucked in to the port of powder wheel during vacuum according to the piston length different fill size can be achieved. The excess powder is doctored off by a doctor blade. Doctor blades can be adjusted from outside also without removing powder hopper. When powder wheel indexes further and remain in the port due to the vacuum till it reaches just vertically above the container. The time dose of Compressed air (Nitrogen Gas), sterilized low pressure air sequentially flushes out powder from the port of powder wheel in to the container one by one. The filled containers are immediately separated on the conveyor by vial separator and moves further for Stop Pering operation. (Different grooves separator can be used which depends on the container diameter or multiple dosing systems). The sterilized, silicon zed, rubber stoppers stored in the vibrator bowl moves to vibratory bowl and stacked vertically in the rubber stopper chute. The container is hold firmly between pair or timing belt to pickup rubber stopper from exit end of the chute. Further the container is passed between two pressing roller for tight fit fixing of rubber stopper. |

| Technical Details : | |

| Model | SBPF-240 |

| Direction | Left To Right. |

| Production Rate | Up to 240 Fills / Min for Single Dose. Up to 120 Fills / Min for Double Dose. Up to 80 Fills / Min for Triple Dose.Up to 60 Fills / Min for Four Dose. |

| Fill Capacity | 50mg to 1.5gm Single Dose (with Change Parts) 1.5 gms to 6 gms. Double, Triple and Four Doses. Fill range depending upon vial opening and bulk density of powder. Under controlled level of Humidity (i.e. 25%) |

| Accuracy | ±1% depending upon consistency and uniformity of bulk density of Injectable powder |

| Electrical Supply | 1.00 HP For Main Drive. 0.50 HP For Unscrambler.0.50 HP For Scrambler. |

| Power Requirement | 440 Volts, 3 Phase (4 wire System) 50 Hz. |

| Height of Conveyor | Adjustable from 800 To 850 MM |

| Dimensions | 3028 mm (L) x 1093 mm (W) x 1885 mm (H) |

| Net Weight | 800 KGS. (Approx.) |

| Gross Weight | 1200 KGS. (Approx.) |

| Vial Diameter | 25 mm to 45 mm max. |

| Height | 75 mm maximum. |

| Rubber Stopper | 20 mm diameter. |

| Pneumatic Air | Filtered, oil free, sterile low pressure AIR at 2 kg/cm2 (2/3 bar) |

| Vacuum line | 20 HG. (Pump will be supplied by S.B.) |

Salient Features:

- M.S. moulded structure duly powder coated to avoid any vibration with adjustable screws to adjust conveyor height as per in feed tunnel.

- All parts and assemblies coming in contact with powder and rubber stopper are made of S.S.316 and easily removable for

- mandatory Autoclaving/ Sterilization.

- “NO VIAL, NO FILL” System eliminates wastage of costly powder.

- Spring loaded Teflon top seal for powder hopper reduces the friction between and top seal and avoid chance of white particle shading during production.

- Doctor blade and wiper blade can be adjusted from outside also without disturbing any production, which saves lot of time, powder wastage and chances of area condition disturbance.

- All assemblies under top plate are positioned as for easy cleaning or maintenance.

- Multiple dosing of Inject able powder or changeover of container size and different fill size is possible by just changing the vial separator or size of the piston respectively.

- All driving is through High quality imported Gear motor for better machine performance without vibration or leakage of oil of area floor from gear box.

- Machine speed can be adjusted through A.C. Frequency drive, which is time saving and easy to synchronize Unscrambled and scrambler speed with machine speed.

- Machine is provided with delrin conveyor belt to avoid sticking of vial on conveyor.

- Special clutch devices are provided on vial separator for safety purpose.

- Vibratory bowl for rubber Stoppering unit support to run machine with total claimed speed of machine.

- Air filter will be of S.S.316 housing with Nylon cartridge for proper removal of particle of 0.22 micron having 10″ length.

- Vacuum filter will be of PVC transparent material with nylon cartage having length of 10″.

- Imported Gear Motor for Main drive, Unscrambled and scrambler.

- A.C. Frequency drives for Main drive, Unscrambled and Scrambler.

- Pre and Post Gassing unit for Nitrogen or Carbon Dioxide flushing.

- Pure air filters for Air and Vacuum.

- “No Vial, No Filling System”.

- “No Stopper in Chute, Machine Stop System”

- Vacuum pump.

- Acrylic Cabinet with Imported Aluminium Structure for Machine, Unscrambled and Scrambler

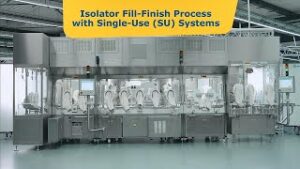

Each Automatic filling line includes equipment from Washing to Packing (Cleaning & Washing, Drying, Filling, Capping, Aseptic Containment Isolator System, Inspection, Labeling, Turn Table, Cartooning machine, Conveyors with Laminar, HEPA, Glove port, 21 CFR, ISOLATOR, PLC with Touch Screen, RABS and Isolator technology etc…

- Injectable Ampoules Filling Lines

- Injectable Liquid Filling Lines

- Injectable Powder Filling Lines

- Oral Liquid/Syrup Filling Lines

- Dry Syrup Powder Filling Lines

Complete integrated line consisting of following machine:

- Vertical rotary vial washing machine.

- Sterilizing & dehydrogenating tunnel

- Liquid vial filling & bunging machine with statistical / 100% check weighing under isolator.

- Transfer conveyors with isolator

- Automatic lyophilize loading & unloading system with isolator.

- Vial cap sealing machine with isolator.

- External vial washing machine with isolator.

Vial filling machine with Laminar , HEPA , Glove port, 21 CFR , ISOLATOR , PLC with Touch Screen , RABS and Isolator technology

Salient Features of Isolator:

Vial filling machine with Laminar , HEPA , Glove port, 21 CFR , ISOLATOR , PLC with Touch Screen , RABS and Isolator technology

- Positive pressure isolator for aseptic processing of OEB5 product

- Rigid wall construction in SS316L

- La – calhene RTP & LTP

- Monitoring & controlling of pressure, temperature & RH

- AHU for supply & exhaust air with recirculation system

- Air exhaust through bag in bag out (BIBO) unit – safe change double HEPA filters

- WIP gun & spray balls for CIP

- Automatic leak testing

- Integrated VHP system for sterilization

- SCADA Integration 21 CFR part 11 compliance

For more details, reach us at +91 989807 0475 or write to us at info@multipackmachinery.com

Manufacturer Wide range of injectable powder filling machines, vial powder filling machine, dry injection filling machine, vial dry powder filling machine, Injectable dry powder filling machine and sterile dry powder filling machine, Aseptic filling machine manufacturers , aseptic filling machine pharmaceutical , aseptic vial filling equipment , Injectable Liquid Filling Machine, Liquid Filling Machine, Injectable Dry Powder Filling Machine, Dry Powder Filling Machine, Rubber Stoppering Machine, vial filling machine, injectable liquid filling machine, Injectable Liquid Filling Machine, Injectable Vial Filling line , Automatic Injectable Powder Filling with Rubber Stoppering is a compact model used for filling Stoppering of Dry Powder Injectable in to vials with Laminar , HEPA , Glove port, 21 CFR , ISOLATOR , PLC with Touch Screen , RABS and Isolator technology etc…

| brand | |

|---|---|

| color | |

| material |

Related products

-

Double Head Auger Type Powder Filling Machine

₹1200000.00SBAF-D-100 Automatic Double Head Auger Type Dry Syrup Powder Filling Machine is a compact model used for filling Dry Syrup Powder in bottles,Our Machine suitable for dry syrup, talcum, spices powder, flour Free Flowing Powders Chemicals, Pharmaceutical Powers, Food & Beverages, Cosmetics powder, Pesticides Powder

-

Auger Filler Machine for Metal Tin / Jar

₹850000.00Auger filler is Semi-Automatic Powder Filling Machine. Auger filler ,also known as semi automatic powder filler which is used to fill accurate weight size of powder in bottles, pouches

-

Single Head Rotary Dry Syrup Powder Filling Machine

₹750000.00Our Auger powder filling Machine suitable for dry syrup, talcum, spices powder, flour Free Flowing Powders Chemicals, Pharmaceutical Powers, Food & Beverages, Cosmetics powder, Pesticides Powder etc.

We Export Machines in Following Countries:

We export Bottle & Automatic Injectable Dry Powder Filling With Rubber Stoppering Machine SBPF-240 GMP Model to Afghanistan , Albania ,Algeria ,Andorra , Angola , Antigua and Barbuda , Argentina , Armenia ,Aruba , Australia , Austria , Azerbaijan , Bahamas, The Bahrain , Bangladesh , Barbados ,Belarus , Belgium , Belize ,Benin ,Bhutan , Bolivia , Bosnia and Herzegovina , Botswana , Brazil , Brunei , Bulgaria , Burkina Faso , Burma , Burundi , Cambodia , Cameroon , Canada , Cabo Verde , Central African Republic , Chad , Chile , China, Colombia,Comoros ,Congo, Democratic Republic of the Congo, Republic of the Costa Rica , Cote d'Ivoire , Croatia , , Curacao ,Cyprus , Czechia , Denmark ,Djibouti , Dominica , Dominican Republic ,East Timor (see Timor-Leste) , Ecuador , Egypt , El Salvador , Equatorial Guinea , Eritrea , Estonia ,Ethiopia , Fiji , Finland , Gabon , Gambia, The Georgia , Germany , Ghana , Greece , Grenada , Guatemala ,Guinea , Guinea-Bissau ,Guyana,Haiti , Holy See , Honduras , Hong Kong ,Hungary ,Iceland , India , Indonesia , ,Iraq , Ireland ,Israel ,Italy , Jamaica , Japan , Jordan , Kazakhstan , Kenya , Kiribati , Korea, , South Kosovo ,Kuwait ,Kyrgyzstan , Laos , Latvia , Lebanon , Lesotho , Liberia ,Libya , Liechtenstein , Lithuania , Luxembourg , Macau , Macedonia , Madagascar, Malawi , Malaysia , Maldives , Mali , Malta , Marshall Islands ,Mauritania,Mauritius , Mexico, Micronesia , Moldova , Monaco , Mongolia , Montenegro , Morocco , Mozambique , Namibia , Nauru , Nepal, Netherlands , New Zealand , Nicaragua , Niger , Nigeria , ,Norway,Oman , Pakistan , Palau , Palestinian Territories ,Panama , Papua New Guinea ,Paraguay , Peru , Philippines , Poland , Portugal ,Qatar , Romania , Russia , Rwanda , Saint Kitts and Nevis , Saint Lucia ,Saint Vincent and the Grenadines , Samoa , San Marino , Sao Tome and Principe , Saudi Arabia , Senegal, Serbia , Seychelles , Sierra Leone, Singapore , Sint Maarten , Slovakia, Slovenia, Solomon Islands , Somalia, South Africa , South Korea,South , Spain , Sri Lanka , , Suriname , Swaziland , Sweden , Switzerland , ,Taiwan , Tajikistan , Tanzania ,Thailand , Timor-Leste, Togo , Tonga, Trinidad and Tobago ,Tunisia ,Turkey ,Turkmenistan,Tuvalu, Uganda , Ukraine , United Arab Emirates, United Kingdom , Uruguay ,Uzbekistan , Vanuatu , Venezuela ,Vietnam , Yemen , Zambia , Zimbabwe

After Sales Service

We manufacture and export Automatic Injectable Dry Powder Filling With Rubber Stoppering Machine SBPF-240 GMP Model at comparatively lowest price with excellent after sales service across the globe. Our customer support department comprising of experts in various branches of engineering are always ready to attend to any urgent requirement of maintenance or after sales service from our valued customers. Our regional offices are also equipped with qualified service technicians to attend to regional customer’s service calls promptly. A separate team of service personnel for our international customers is always on its toe to proceed to any location world over. We have trained engineers deputed at some of our international agent’s place for quick after sales service.